Categories

New Products

800LE+ Self-propelled Concrete Floor Grinder With Gear-driven 800LE+ Self-propelled floor grinder and versatile polisher are used to grind (rough grind, fine grind, and polish) concrete, natural stone and terrazzo floors or other materials. With a self-propelled function, it realizes higher grinding efficiency with lower labor costs. The design of the planetary rotating system makes the grinding effect uniform and stable. More

GX550 Concrete Floor Grinder GX550 Concrete Planetary Grinding machine has 3 planetary heads with very low maintenance. The stronger welded machine body with friendly operation handle and 2 positions weight iron to adjust the pressure when you are working. All motor and inverter are from the newest technology special for XINGYI grinding machine. More

Heavy-Duty Remote Control Planetary Concrete Grinding Machine XINGYI GX858 GX858 Concrete Grinder is a remote control heavy-duty equipment for your polishing project, the machine has 4 planetary heads with very low maintenance. The stronger welded machine body with friendly operation handle and 2 positions weight iron to adjust the pressure when you are working. All motor and inverter are from the newest technology special for XINGYI grinding machine. More

Ride on floor grinder Tank1500 is a very suitable for industrial applications, low-maintenance, smooth-running on-board grinding and polishing machine, gearbox, completely sealed and dustproof. More

GX750 Heavy-Duty Concrete Grinding Machine GX 750 Planetary Concrete GRINDING MACHINE GX750 is a heavy-duty equipment for your polishing project, Thanks to XINGYI dual Alloy gearbox casting technology, the machine has 3 planetary heads with very low maintenance. The stronger welded machine body with friendly operation handle and 2 positions weight iron to adjust the pressure when you are working. All motor and inverter are from the newest technology special for XINGYI grinding machine. More

GX650 Concrete Grinding and Polish machine GX 650 / GX 65 ROTARY Concrete GRINDING MACHINE The GX650 has 4-heads which works in counter rotary direction and provide smooth of operation and handling. Collapsible hand grip for easier transport and adjustable to your perfect working position. Dual-purpose additional weight makes your construction easier.Its versatile function from floor preparation to fine polishing, suitable for concrete, stone, epoxy coating, terrazzo and other floors. The 17 years of classic design with worry-free quality.*GX65 is equipped with fixed handle. More

GX550 Concrete Floor Grinder GX550 Planetary concrete grinder,Same with other GX series machine, the machine has 3 planetary heads with very low maintenance. The stronger welded machine body with friendly operation handle and 2 positions weight iron to adjust the pressure when you are working. All motor and inverter are from the newest technology special for XINGYI grinding machine. More

955LE large polishing floor grinding machine Features and Advantages 1.Intelligent remote control, millisecond response. 2. S-type grinding greatly improves the grinding force. 3. The equipment comes with a spray system:The spray system can quickly reduce the temperature of the abrasive to improve the grinding efficiency. Using the spray function can also reduce dust. 4. Dual clutch design:The drive system is firmer and more suitable for rotten ground. More

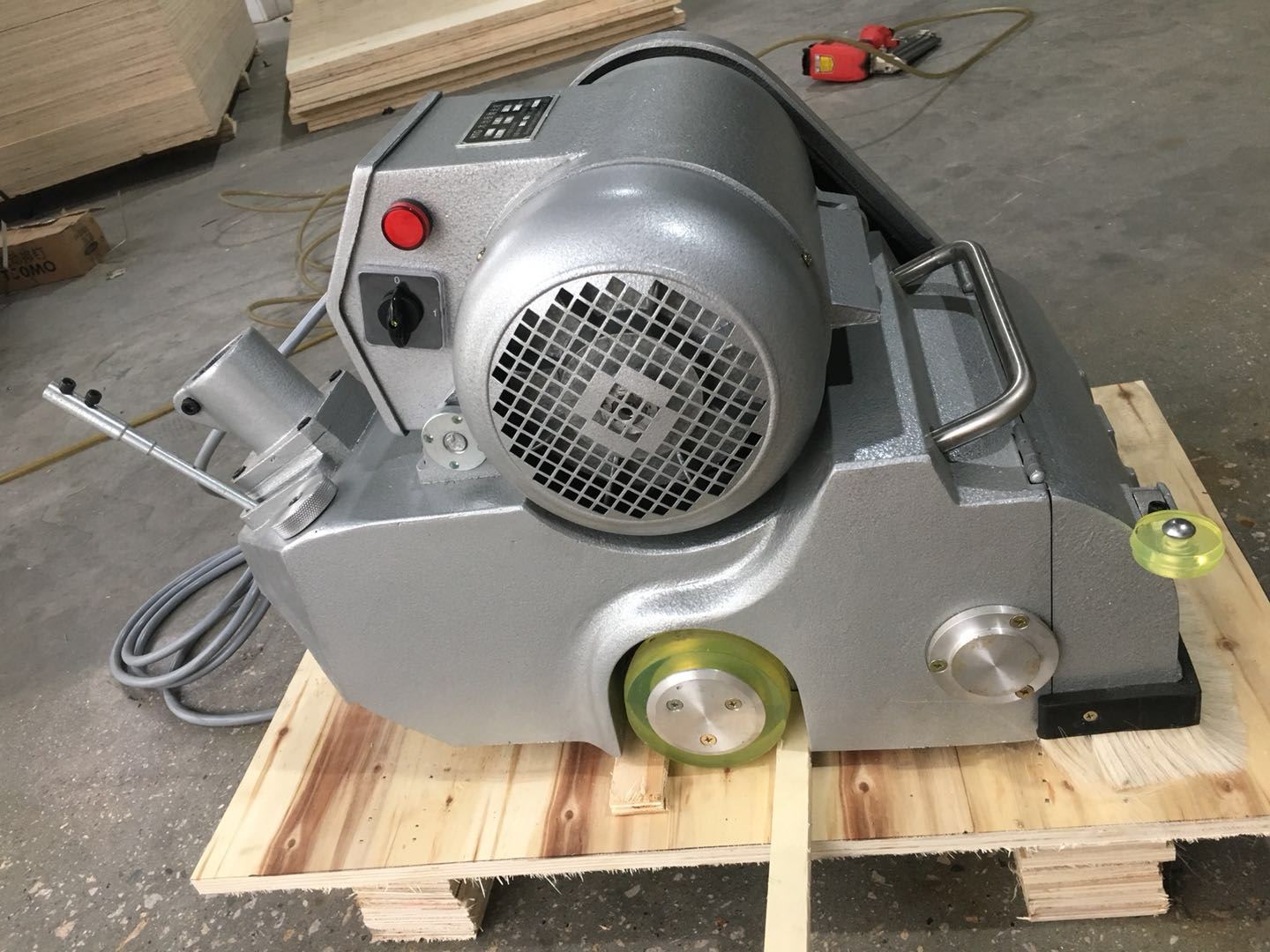

HTG-XY300A wood polishing machine is a polishing machine suitable for all kinds of new and old wood floors.

Brand:

High Tech GrindingItem NO.:

HTG-XY300AProduct Origin:

Fujian, ChinaColor:

silverShipping Port:

XiamenLead Time:

7-20 DaysEasy operate wood floor sanding machine

This potable wood floor polishing machine is specially designed for the processing of large-scale floor surfaces in schools, gymnasiums and factories. The characteristics of HTG-300A are strong working mode, perfect processing quality, high efficiency of dust collection device and low dust pollution.

Specification

|

Model Name |

300A |

|

Working Width |

300mm |

|

Voltage |

220V |

|

MotorHP |

3KW/4HP |

|

Rotating Speed |

2080rpm |

|

Packing size |

85*56*66cm |

|

Weight |

98kg |

(1) Suit for all kinds of new and old wood floors, grinding direction won't be influenced by wood texture.

(2) Easy operation, safe, high efficiency with low noise.

(3) Working width of cylinder is 300mm which suits for large-area construction projects.

(4) With on electric motor as the source power, machine grinds the wooden floor by two different types of belt which is used to drive the cylinder and dust collector.

Wood floor polishing and renovation steps:

1. First, find a professional floor polishing and refurbishing machine, and perform several polishing to remove the paint layer and the surface layer. The wooden layer is about 0.5 mm to make the floor surface more delicate and smooth to a new state. For the corners of the floor, use small The sanding machine is used for sanding to achieve an overall smooth effect.

2. Seal the original side seams again, then seal the whole floor with primer and let it dry slowly.

3. After the primer is dry, apply the topcoat for the first time and wait for it to dry.

4. Grind the surface carefully with sandpaper, grind the surface until it is rough, and remove the powder on the surface.

5. Brush the topcoat three to four times in accordance with the above procedure, and no grinding is necessary for the latter time.

6. After the top coat is completely dry, apply the floor wax.

Customer demo

Product packaging

FAQ

1. Can you leave concrete floors bare?

Bare concrete floors might often be the cheapest option, but they can lead to a whole host of problems that could incur more costs, hassle, and lost time than installing a coating in the first place.

2. What are the best shoes to wear on concrete floors?

The best shoes for walking or working on concrete floors are Timberland PRO Men's Sports Shoes and Skechers Men's Glides Calculous Loafer. They are comfortable athletic work shoes for walking / standing on the concrete floors for long hours.

3. Is unsealed concrete toxic?

When you leave your concrete warehouse floors unsealed, the concrete will produce flecks of concrete dust that can coat machinery, create a dirty work environment, wreaking havoc on manufacturing, and even cause health issues. It's simply unavoidable and a very real issue unless you seal the floors.

4. Why need a concrete floor grinder?

When it comes to all-in-one construction tools, a concrete floor grinder is a must. Whether the job involves grinding down uneven concrete slabs, leveling joints, removing stubborn tile, vinyl glue, paint, or giving a concrete surface a smooth appearance or even cleaning industrial contaminants, these powerful machines eliminate the need for chemical etching, making quick work out of concrete surfacing jobs both big and small.

Most grinders are made to handle dry and wet surface jobs. Successful grinding requires proper clean-up and disposal of the concrete dust or slurry created by the process.

Contact us

Email: xingyi19@polishingmachine.cc

Whatsapp: 008615960731060

Enable the global floor labors to work with health, Easy and happiness

Copyright © 2015-2025 Fujian Xingyi Intelligent Equipment Co., Ltd.All Rights Reserved.dyyseo.com